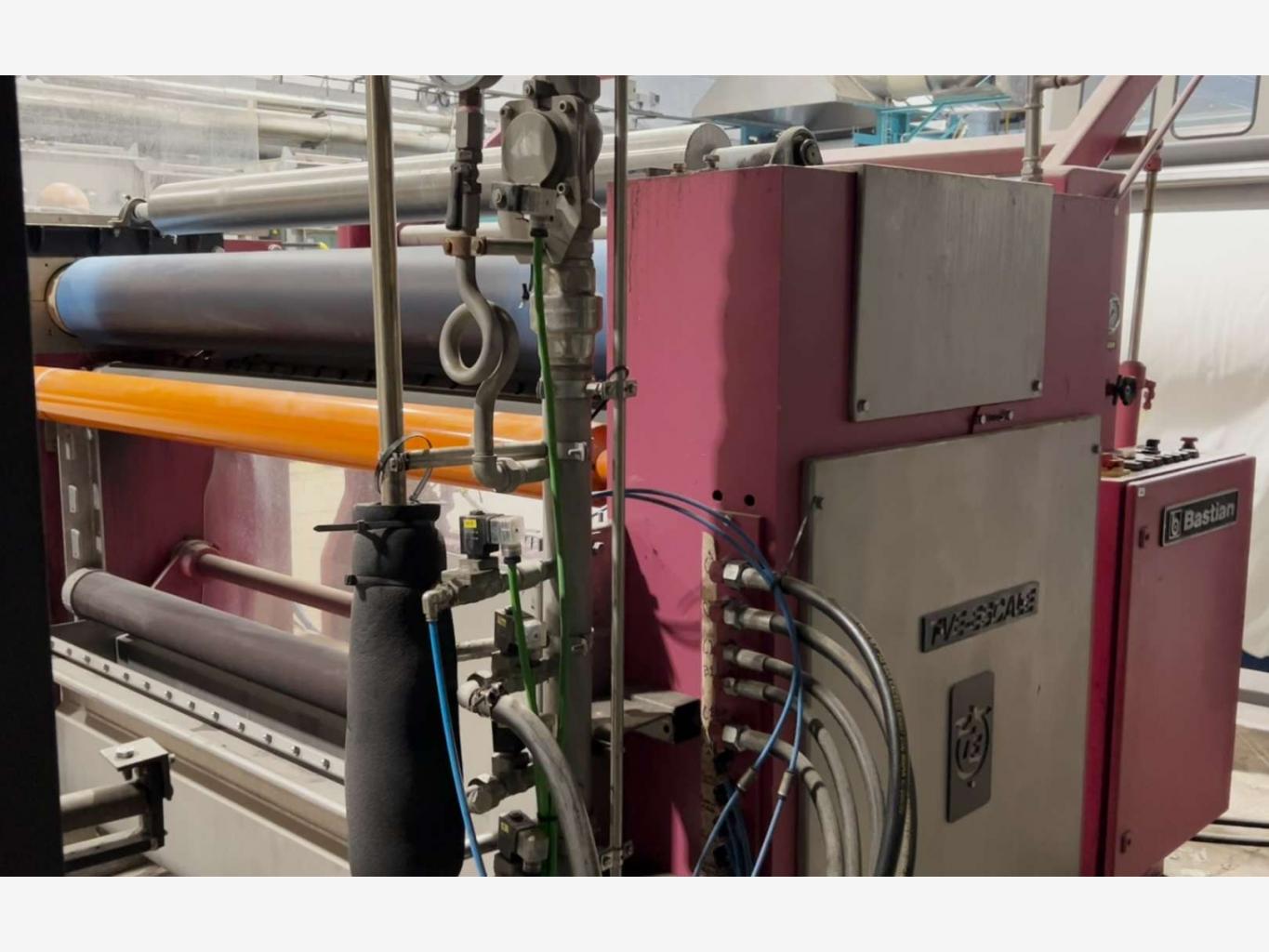

KUSTERS DYEING PADDER Year 2006 Working width 1800 mm

- Brand : KUSTERS

- Year : 2006

- Working width : 1800 mm

- Model : 222.11.1800

- More info: : Fully reconditioned by COMATEX in 2006

- Number of Bowls : 2

- Roller Width : 2000 mm

- Used textile machine : Yes

Machine description

KUSTERS COLD PAD BATCH DYEING, RE-CON YEAR 2006

TYPE-222-11-1800 RECONDITIONED TO ORDER 2024

SUITABLE FOR COLD PAD BATCH DYEING, (ORIGINAL YEAR 1991)

PRE-TENSION ENTRY, E+L KF20 GUIDERS MOUNTED ON A MANUAL ADJUSTER RAIL

2 ENTRY PATH ROLLERS IN 316 STAINLESS STEEL. Not supplied with the machine

LIQUOR TROUGH APPROX 55 LITRES, LIQUOR CONTENT CONSTRUCTED IN 316 STAINLESS STEEL WITH COOLING JACKET.

1 - TROUGH ROLLER (THREE WAS MISSING), PNEUMATIC LIFTING AND LOWERING WITH LIQUOR LEVEL SENSING TO SIGNAL

ONE ADJUSTABLE RUBBER COVERED EXPANDER BOW ROLLER

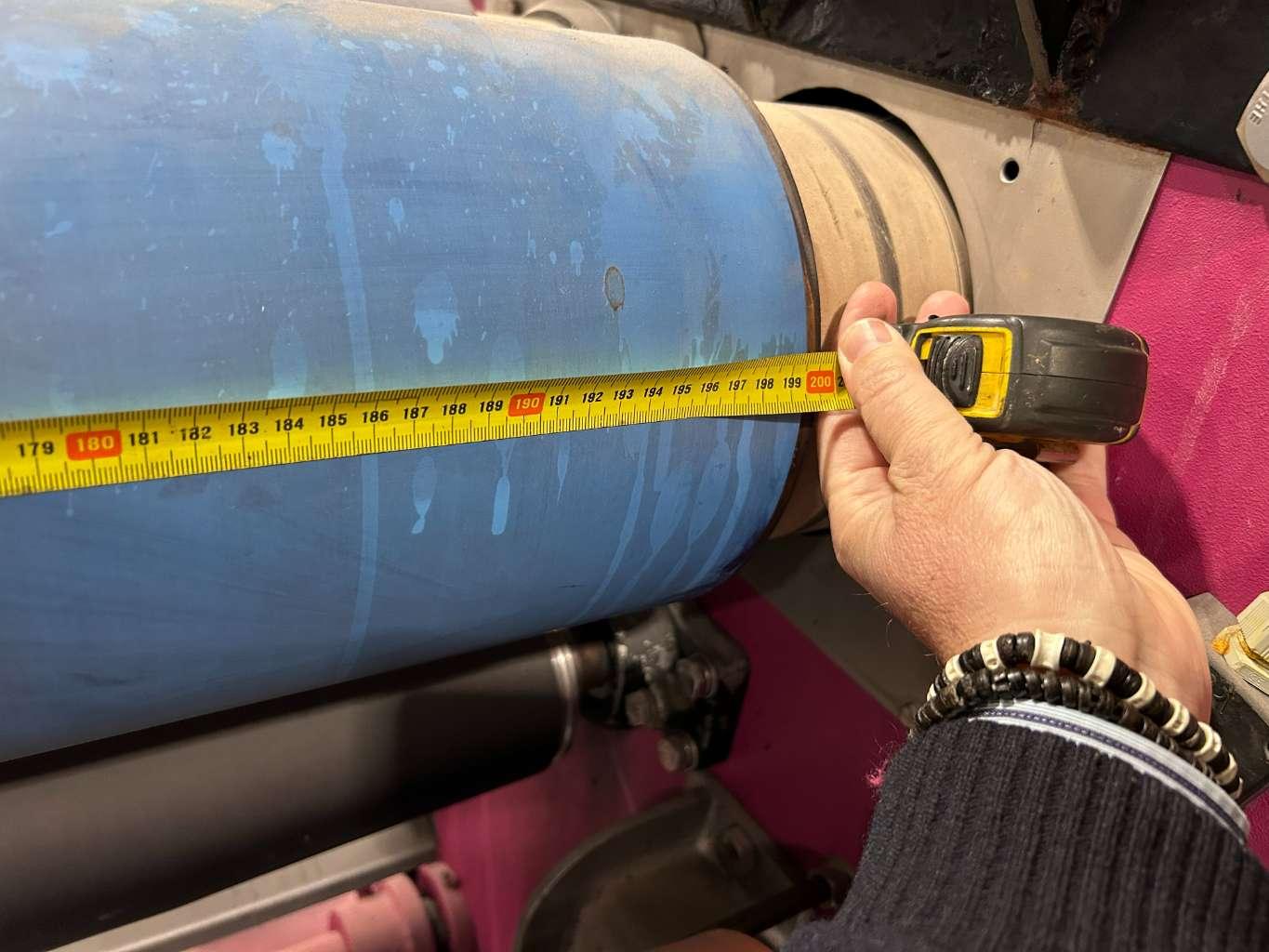

2 - SWIMMING ROLLERS 220MM DIAMETER, COVERED WITH PVC NITRILE RUBBER SHORE HARDNESS 65

THE TWO HYDRAULIC SWIMMING ROLLERS ARE HORIZONTALLY OPPOSED TO GIVE A VERTICAL FABRIC LINE, THE SQUEEZE PRESSURE IS CONTROLLED VIA THE INFINITELY VARIABLE HYDRO PNEUMATIC CONTROL SYSTEM WITH 3 PRECISION PRESSURE REGULATORS PRODUCING PERFECTLY EVEN EXPRESSION ACROSS FACE OF ROLLERS

2 STAINLESS STEEL SPRAY PIPES TO WASH SQUEEZE ROLLERS, SAFETY NIP GUARDS WITH EMERGENCY STOP WIRE FITTED TO COMPLY WITH EUROPEAN CE MARKINGS

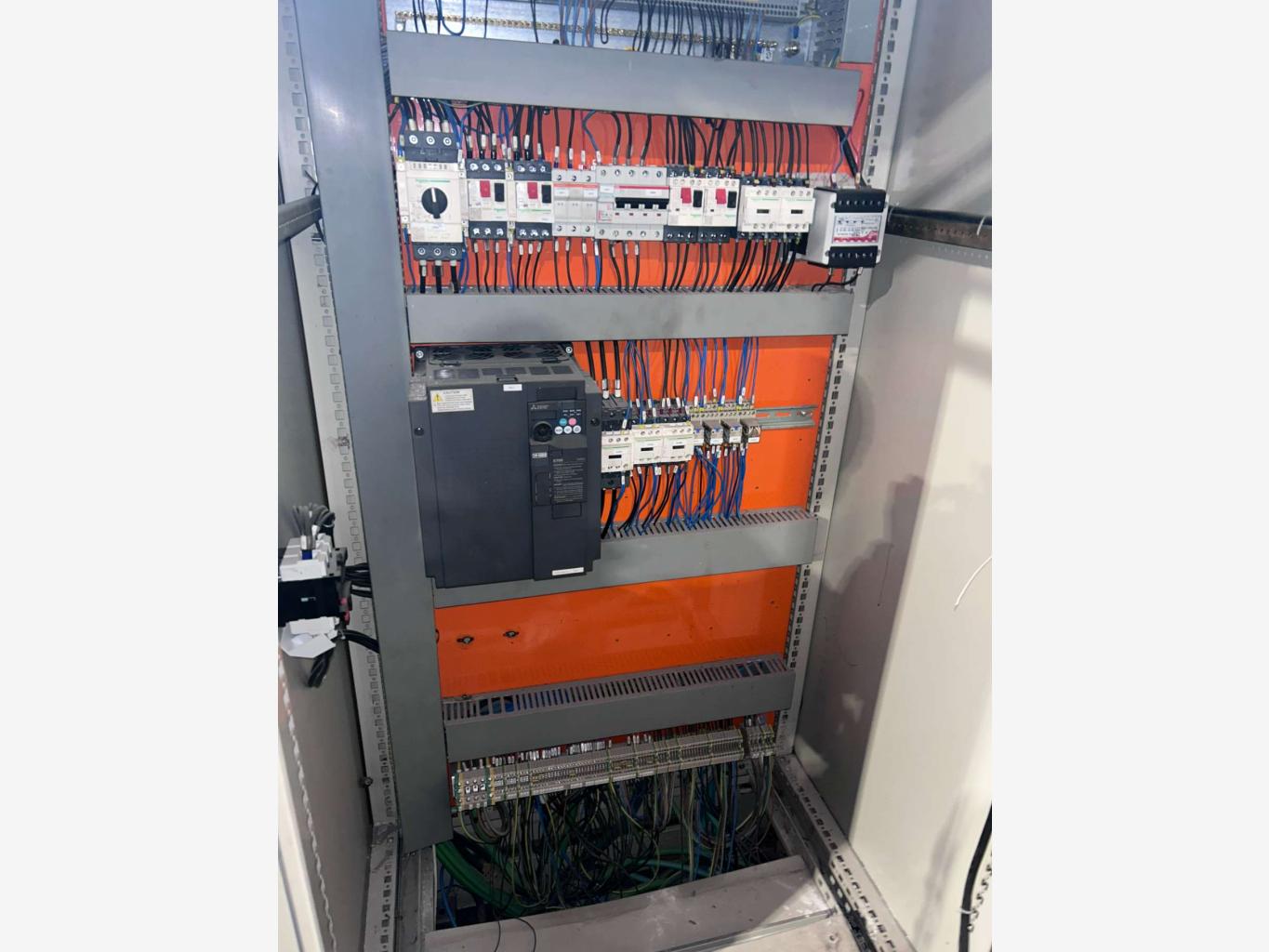

NEW MAIN DRIVE SIEMANS 11 KW AC 415 VOLTS 50 HZ RIGHT ANGLED GEARED MOTOR CONTROLLED BY ELECTRONIC VARIABLE SPEED INVERTER MOUNTED IN NEW IP55 CONTROL PANEL INFINITELY VARIABLE SPEED CONTROL 0-60 METERS PER MINUTE

FACILITY TO RECEIVE A VOLTAGE SIGNAL VIA A TACHO GENERATOR FROM ANY SELECTED MASTER DRIVE

STAINLESS STEEL OPERATORS REMOTE STATION WITH AUTO-MANUAL CONTROLS

TAKE OFF ON TO A BASTIAN CENTER WIND NONE CONTACT BATCHER

(NOT WITH THE MACHINE SERA 4-1 RATIO DOSING PUMP)

2 X 500 LITRE MIXING TANKS WITH MIXERS

RECONDITIONING WORK AS FOLLOWS:

Completely strip the machine down to its individual components shot blast clean and repaint all reusable parts.

Mechanical work

Fabricate entry framework and fit an E+L KF 20-20 guider system

Replace all necessary transmission parts such as bearings belts and chains

All new fasteners such as nuts and bolts.

Recondition all geared drives and fit with new motors or rewind the original motor

Re grind or Recover with new rubber the 2 S rollers

Supply and fit 3 rubber covered tank rollers

Recover with new rubber the 1 bow roller

Recover with new rubber tape covering the fabric batch draw roller

Polish all ss path rollers and stainless-steel trough

Re calibrate the 2 S rollers ready to run

Electrical work?

Upgrade operators touch screen control panel with new AC inverter by ABB or Siemens all new cables & safety switches from the main control panel to the motors and switches.

More images

Spanish

Spanish